Home > Company News > Stainless Steel Filter Mesh

Company News

Anping Qianpu Wire Mesh Products Co., Ltd

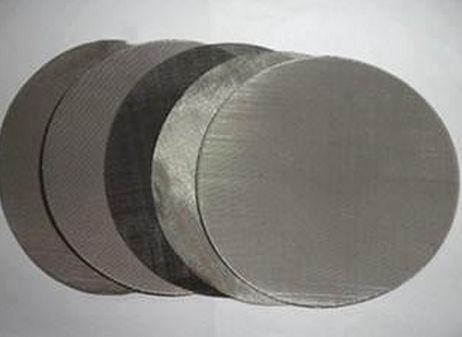

Stainless Steel Filter Mesh is a versatile and essential material used for filtration and separation processes across various industries. It is characterized by its mesh structure made from stainless steel wire or stainless steel plate, offering high durability, strong corrosion resistance, and high-temperature tolerance. Here is an introduction to stainless steel filter mesh, including its material properties, applications, and types:

Material Properties:

Stainless steel filter mesh is made from stainless steel, which is an alloy of iron with a minimum of 10.5% chromium. The chromium content provides a passive film that protects the mesh from corrosion, making it suitable for use in harsh environments. Common grades used in filter mesh include:

304 Stainless Steel: Known for its excellent overall performance and corrosion resistance in various applications.

316 Stainless Steel: Offers higher corrosion resistance, especially in environments containing chlorides, and is often used in marine environments and chemical processing.

Applications:

Stainless steel filter mesh is widely used in a range of applications due to its strength, durability, and resistance to corrosion and high temperatures. Some common applications include:

Industrial Filtration: Used in chemical processing, oil and gas, and water treatment to filter impurities from liquids and gases.

Food Processing: Employed for sieving and filtering products to ensure food safety and quality.

Pharmaceuticals: Utilized in drug filtration and particle size analysis for quality control.

Water Treatment: Used in drinking water treatment, wastewater treatment, and pool purification.

HVAC Systems: Installed in heating, ventilation, and air conditioning systems to remove airborne particles.

Automotive Industry: Used as fuel and oil filters to protect engines and extend their life.

Types:

Stainless steel filter meshes can be classified into various types based on their manufacturing processes and performance characteristics:

Woven Mesh: Created by interlacing stainless steel wires to form a grid structure, offering flexibility and strength.

Welded Mesh: Formed by welding stainless steel wires at specific intervals, providing a sturdy and durable screen structure.

Etched Mesh: Produced by perforating stainless steel plates using chemical etching technology, ensuring precision and uniformity in the mesh apertures.

Manufacturing Process:

Stainless steel filter meshes can be manufactured using different methods, including weaving, welding, and chemical etching. Each method offers unique advantages and is suited to different applications.

Weaving: Involves interlacing or weaving stainless steel wires to create a mesh with specific strength and flexibility.

Welding: Involves welding stainless steel wires at specific intervals to form a sturdy and durable screen structure.

Chemical Etching: A process that allows for the creation of complex mesh designs and high-density hole distributions, meeting stringent filtration accuracy and strength requirements.

Benefits:

Precision and Consistency: Chemical etching technology offers high precision and consistency in aperture size, shape, and distribution.

Durability and Low Maintenance: Stainless steel filter meshes are less likely to accumulate dirt, making them easier to clean and maintain.

Cost-Effective for Large-Scale Production: Chemical etching technology allows for cost advantages in large-scale production due to its mold-free manufacturing process.

Stainless steel filter mesh is a critical component in many filtration systems, providing reliable performance and longevity. Its versatility and material properties make it an ideal choice for a wide range of industrial and domestic applications.