Home > Company News > Stainless Steel Woven Mesh

Company News

Anping Qianpu Wire Mesh Products Co., Ltd

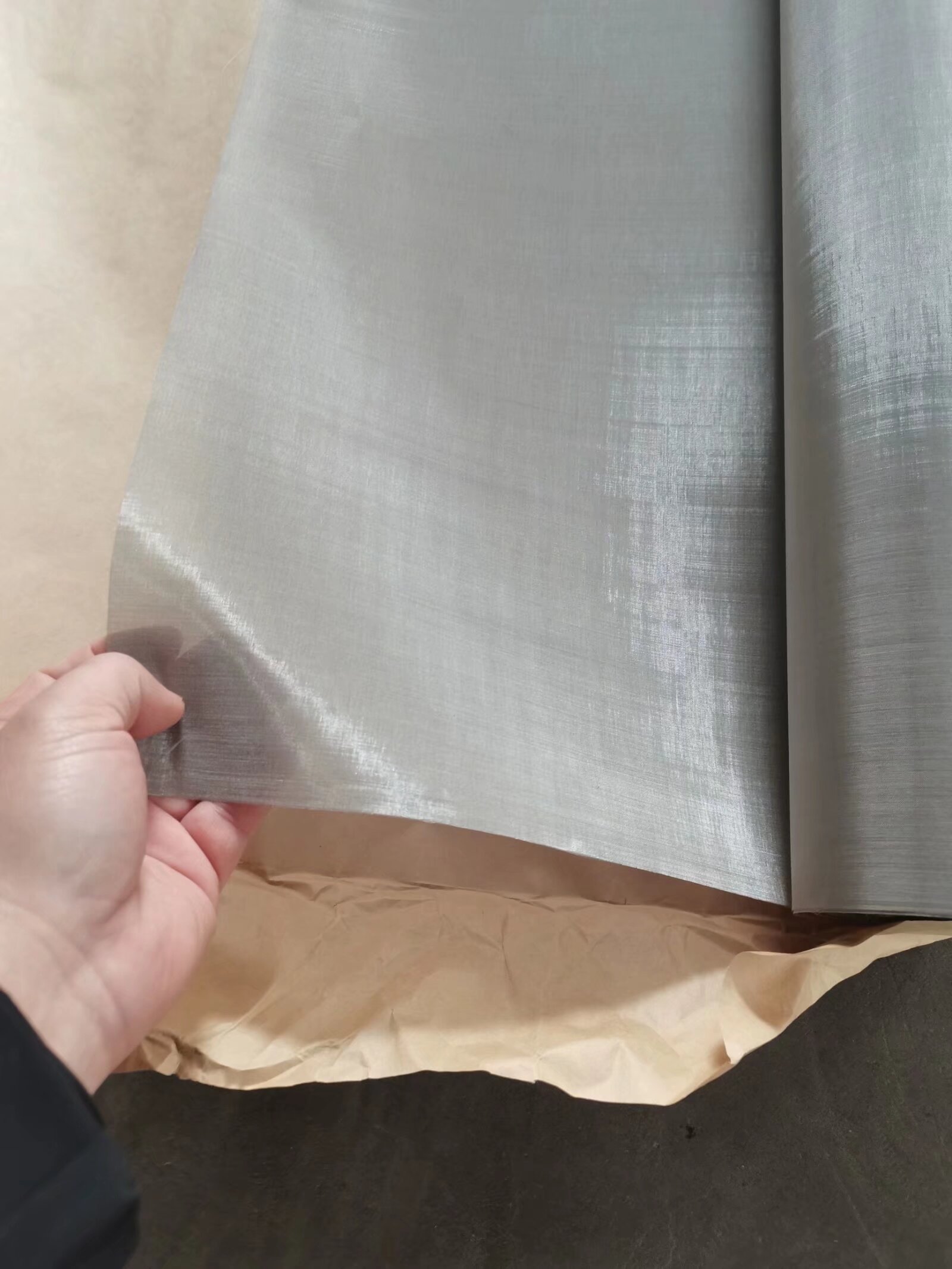

Stainless Steel Woven Mesh is a versatile and durable filtering medium that is woven from stainless steel wires of varying diameters. It is known for its precision filtering properties and is widely used across a spectrum of industries due to its ability to achieve high filtering densities. Here is an overview of stainless steel woven mesh:

Material and Construction:

Stainless steel woven mesh is constructed using warp and weft wires with different diameters, creating a mesh with a high density. Typically, the warp wire diameter is larger than the weft wire diameter, with the exception of contrast weave styles where the weft wire is significantly thicker.

Common Weave Types:

Plain Weave: In this weave, each warp and weft wire alternates over and under each other.

Twill Weave: This weave features a diagonal pattern, with each weft wire passing over two warp wires and under the next two.

Dutch Weave: Also known as twill weave, this style uses thicker warp wires and thinner weft wires to create a more open and robust mesh.

Applications:

Stainless steel woven mesh is utilized in a variety of applications due to its strength, corrosion resistance, and sanitary properties. It is commonly found in:

Fuel Filters: Used in the automotive and aviation industries for fuel filtration.

Precision Pressure Filters: Employed in chemical processing and food processing to remove fine particles.

Vacuum Filters: Used in applications where a vacuum is applied to facilitate the filtration process.

Industrial Strainers: Installed in pipelines to prevent blockages and protect equipment.

Characteristics:

High Filtration Density: Capable of achieving very fine filtration down to micron-level particles.

Corrosion Resistance: Stainless steel's natural resistance to corrosion makes it suitable for use in harsh environments.

Temperature Tolerance: Able to withstand high temperatures, making it ideal for use in heat-intensive processes.

Sanitary Surface: Smooth and easy to clean, making it a popular choice in food and pharmaceutical applications.

Customization:

Stainless steel woven mesh can be customized to meet specific requirements, including:

Mesh Size: The size of the openings can be tailored to the application's needs.

Wire Diameter: The thickness of the wire can be adjusted for different strengths and filtration capabilities.

Width and Length: The mesh can be produced in various widths and lengths to fit specific equipment or structures.

Maintenance and Durability:

Due to its stainless steel composition, the mesh is low-maintenance and durable, with a long service life that reduces the need for frequent replacements.

In summary, stainless steel woven mesh is a high-performance filtering material that offers a combination of strength, corrosion resistance, and precision filtering capabilities, making it an ideal choice for a wide range of industrial and commercial applications.